Manufacturing

Pattern

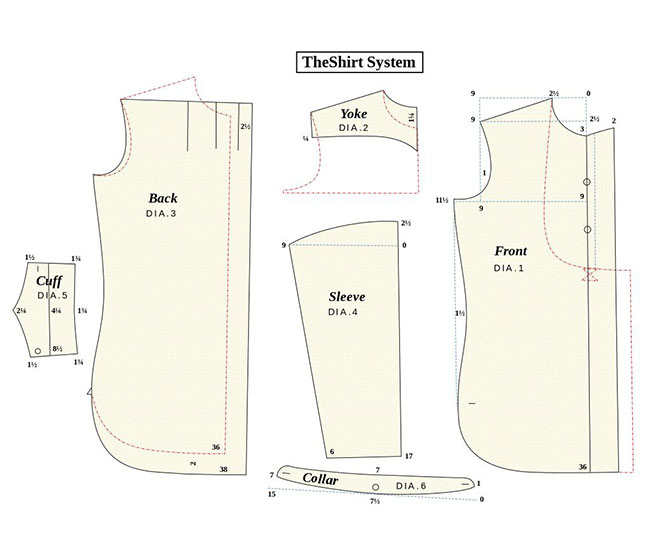

Before making an apparel of garments, designers must have to design or sketch the appearance completely. Every piece of apparel or garment is built upon a pattern. The pattern maker now develops first pattern for the designs in any one size. This is made by pattern drafting method and the purpose of making this pattern is to create the sample garment for test fit. Later these sketches are analyzed by a panel of designers. They finally select few out of them

Cutting

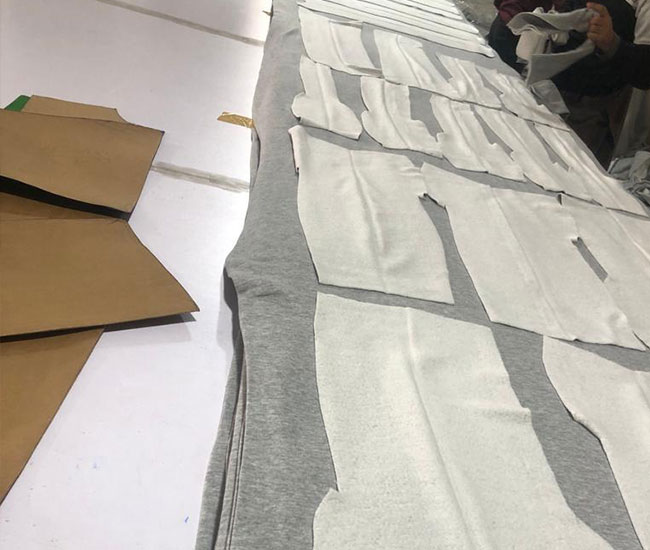

Cutting department is one of the most essential sections for garments manufacturing in the apparel industry. This is a process which we strictly follow because once the fabric has been cut, very little can be done to rectify the mistakes. Using the markers made from graded patterns and in accordance with the issue plan, fabrics are cut to prepare garment assembly. The fabric cutting is started after completing the fabric spreading in the cutting section, the fabrics are cut according to the pattern. Perfect fabric cutting depends on the method of cutting and marker planning.

Stitching Unit

Sewing section is the most important department of a garment manufacturing industry. Sewing is the process of fastening and attaching two parts of fabric using stitches made with a needle and thread. It is one of the basic steps of apparel manufacturing process. We have a separate management and qaulity control staff for this section to ensure the highest quality. By maintaining the stitching section, an order can be completed on time.

Threading & Checking

In stitching department thread trails and thread chains are not trimmed neatly. Uncut threads and thread trails are trimmed in the finishing department by helpers using auto trims as well as manual thread trimming as per quality requirements. Uncut and loose threads on the garments are considered defects. Checking is the last process before shipping, this is done by a well trained staff to meet the customer requirements.

All garments are checked at the finishing stage for visuals and measurement. Finishing checkers check the complete garment inside and out. Checking is done for garment detailing, such as care labeling and trims. Defective garments may need to repair for stitching and fabric defects.

Packing

Pressed garments are folded in a specified dimension. Tags, such as price tags and hang tags are attached to the garment by means of a kimble gun or threads. Finally, properly folded garments are packed into poly bags as per customer requirements. Individual poly bags are then packed into bigger cartons.

Join Our Newsletter

Subscribe our newsletter for more details and updates.